Our Services

At Hofbauer Optik, we offer tailored solutions for your needs in optical metrology, calibration, training, and reverse engineering. Discover how our services can optimize your production processes and help you achieve the highest precision.

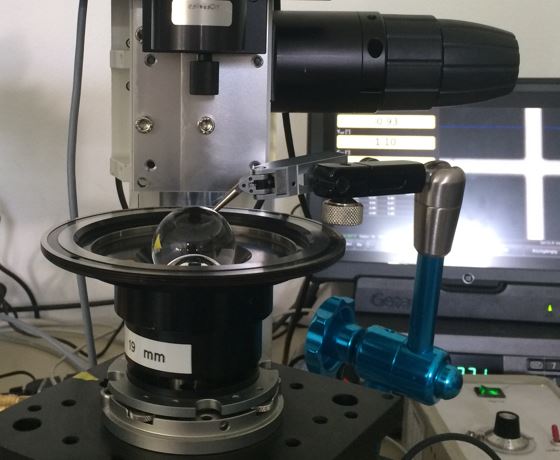

Optical Measuring Instruments

We develop, manufacture, and distribute high-precision optical measuring instruments for various applications – from geometric measurements to spectral analysis. Our systems are modular, configurable, and can be seamlessly integrated into existing production lines. Quality, durability, and user-friendliness are at the heart of our design.

Custom Solutions

In addition to standard devices, we offer custom measuring and testing systems that are precisely tailored to your technical and process-specific requirements. Together with you, we develop customized manufacturing processes, including the required process measurement chain – based on our own ELWISOFT platform and innovative VFS technology. Our approach: precisely calibrated hardware and software solutions, optimally integrated into your production – for maximum efficiency and reproducibility.

Typical application areas:- Rod lens manufacturing

- Achromats & triplets

- Aspherical processing

- Centering adhesive bonding

- Fitting onto mandrels

- Multi-lens software solutions

- V-SPOT applications for position detection

- Multi-SPOT evaluation tools

- Adhesive technologies with process safety

- Integrated rights and user management

Reverse Engineering

With our reverse engineering service, we optimize existing optical components and machines and develop innovative solutions to increase efficiency and reduce costs. By reconstructing components and systems, we make your production even more powerful.

Measurement and Calibration Services

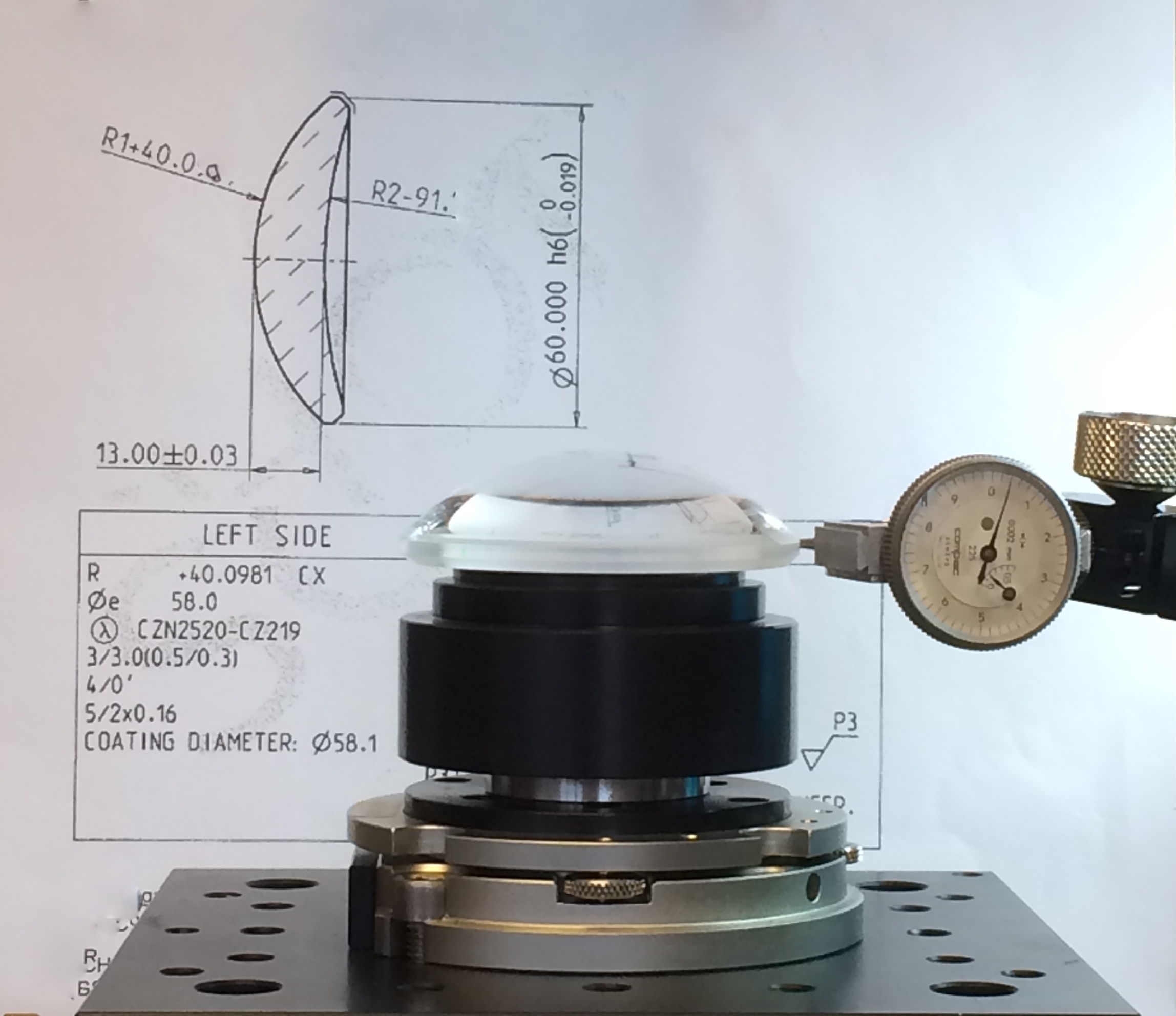

We offer highly precise measurement and calibration services for optical components, machine parts, and production equipment – directly at your location or in our testing laboratory. With state-of-the-art, partly laser-assisted technology, forward-looking software, and decades of experience, we guarantee the shortest measurement times with the highest accuracy and traceability to national and international standards.

Our service offerings:- On-site calibration of machine beds, stands, slides, axes, measuring tables, rotary tables, special machines, and more.

- Precise optical and geometric measurements in machine halls or climate-controlled measurement rooms

- Volumetric compensation and error analysis of machine tools

- Optical calibrations (e.g., refractive indices, radii, angles, focal lengths, centering)

- Results provided as measurement protocols, calibration certificates, or detailed reports

- Straightness/flatness: ± (0.25 to 2) µm/m

- Angle measurement: ± (0.1 to 0.5) angular seconds

- Linear position: ± (1 to 2) µm/m up to 40 m

- Focal length measurement: ± (0.1 to 1) %

- Wedge angle & prism angle: ± (0.2 to 10) angular seconds

- Centering: up to ± 0.2 µm and 0.5 wsec

- Laser interferometers (HP 5529A), BlueLEVEL, ELWIMAT systems

- MÖLLER ELCOMAT, ZEISS Goniometer, refractometers, spheroid meters

- Zygo interferometer, Mahr MFU 300, opto-electronic alignment measuring systems

Training and Consulting

Our practical training courses provide in-depth knowledge in optical metrology, calibration, and the integration of measurement systems. Whether at your location or in our training rooms – we ensure quick familiarization, secure measurement processes, and the efficient use of the latest technologies in your production.

Your benefits:- Higher measurement security and shorter testing times

- Increased motivation and professional development

- Synergies through interdisciplinary understanding

- Fundamentals of metrology (DIN 1319 / GUM)

- Test equipment monitoring: straightness, flatness, tilt angles, tolerances

- Optics: materials, image defects, ISO 10110

- Manufacturing metrology: centering, interferometry, goniometry, MTF

- Software: ELWISOFT, ELWI-GER, ELWI-Center

Optics Design & Tolerance Simulation

We offer comprehensive optics design and perform practical tolerance simulations that are tailored to your specific manufacturing processes and quality requirements. This ensures your products perform optimally and production errors are avoided.

- Design of optical and optomechanical systems

- Tolerance simulation for optical and optomechanical components

Software Solutions for Your Processes

Our tailored software solutions assist you in automating, visualizing, and analyzing your measurement data. Whether it's data management, user interfaces, or integrating measuring systems into your existing IT infrastructure – we develop intelligent tools that make your processes safer and more efficient.

Contact Us

If you have any questions about our services or would like to request a quote, we are happy to assist you and develop the best solution for your optical metrology requirements.

DE

DE  EN

EN